A clutch also for the tough jobs!

Centrifugal clutches for use in wood chippers - reliable and durable!

At Amsbeck Maschinentechnik GmbH we have been manufacturing centrifugal clutches and centrifugal brakes for a wide range of applications since 1982

The wood chipper is one of the toughest applications for the centrifugal clutch. Why that?

When the tree branches are drawn in, high resistance on the shredder drum can occur, which causes the engine speed to drop. If the chipper will then be overloaded with branches, the speed drops too much and the centrifugal clutch starts slipping. Slippage means that the transmitted torque is reduced, and the friction linings of the clutch wear out. In worst case the clutch "burns out" within a very short time – but this can be avoided!

To make sure that the whole system works well, the centrifugal clutch should be designed according to the drivetrain data of the chipper with an appropriate safety factor. Furthermore, it is helpful if the woodchipper is using a so-called "no-stress" or "anti-stress system". These systems ensure that the feeding of the branches will automatically stop, once the engine speed drops down until it is back in the normal range. If the centrifugal clutch and the working range of the chipper fit together, the centrifugal clutch can let the chipper work while the Operator can focus on feeding the chipper with branches.

The centrifugal clutch can let the chipper work - while the Operator can focus on feeding the chipper with branches.

What should be considered when designing a centrifugal clutch for wood chippers?

When designing a centrifugal clutch, particular attention is paid to the working-speed range of the wood chipper. The design basis of the centrifugal clutch is the engine power and working speed of the machine.

The type and size of the clutch is determined based on the discussions with the customer, the technical specification and the application know-how of the Amsbeck Engineers.

A first design proposal will be developed and discussed and approved with the customer. The modular construction system at Amsbeck makes it possible to design the centrifugal clutches individually for each customer and to optimally adapt them to their requirements.

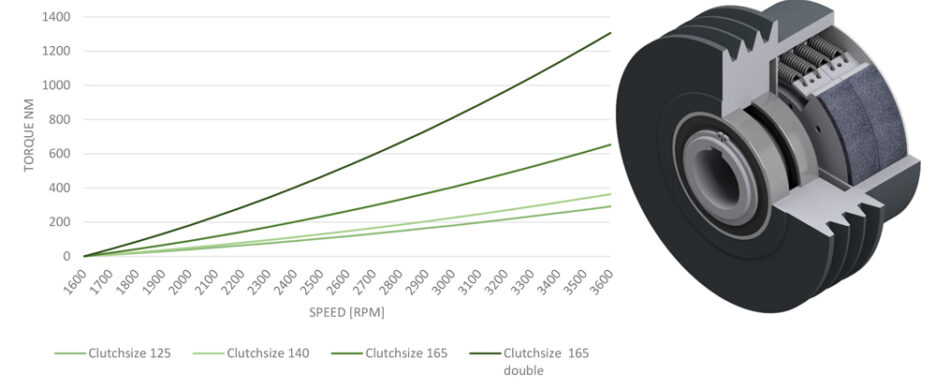

The most common clutch sizes for wood chippers in diameter are 125 mm to 165 mm. However, the Amsbeck standard modular system is designed up to a size of 250 mm, so in the standard range, torques up to 1.000 Nm @ 2.500 rpm can be transmitted.

When designed correctly, the centrifugal clutch is a robust, durable clutch that automatically switches on the chipper at a defined engine speed. Compared to manual operation using a belt tensioner or hand lever clutch, the centrifugal clutch provides a better usability for for the operator. He can focus on loading the wood and let the chipper do the work.

Since a certain amount of wear is unavoidable, Amsbeck offers replaceable friction linings, which can be easily exchanged together with the springs as a set of wearparts. The lifetime of the clutch can thus be extended many times over.

If you want to test your own clutch – just contact us.

Finally, the centrifugal clutch provides a better usability for the operator!

© copyright 2024 | Amsbeck