Get an insight into our company profile here

Centrifugal clutches and centrifugal brakes have been characteristic for the know-how of Amsbeck Maschinentechnik GmbH and the basis for our success since 1982. Over the course of the years, further products were added, such as plug-on and flange-connection gears and hydraulic shifting clutches. Our knowledge built in the course of many years has enabled us to develop into a competent contact for customer specific complete solutions in drive technology. Our in-house development, production and sale at our site in Everswinkel, at the heart of Münsterland, offer our customers short paths, quick decisions and the greatest flexibility for your tasks.

The areas of use of our products are extremely diverse. They can be found in construction machinery, transport cooling systems, pump facilities, blowers, compressors, forestry machinery, agricultural, garden and landscaping equipment technology, as well as cart sports.

We supply high quality! Our quality management has been regularly certified to DIN EN ISO 9001 since 1995.

Our team

We are a medium-sized, family-owned company. We have a team of young and experienced employees. Another, and increasingly important, factor for success is interaction and the connected transfer of experience between highly qualified managers and young technology enthusiasts whom we train in-house. They are our future capital and thus the foundation for our success and growth.

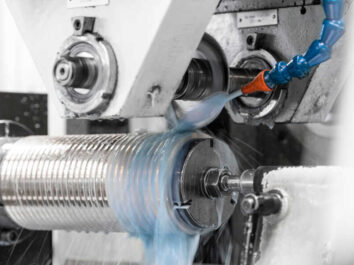

Our production

The requirements specified in the development phase are implemented precisely here with modern CNC machines. The computer-supported manufacturing procedure ensures the best possible fit. Human manipulation is only necessary before the manufacturing step in the scope of programming the machines and later quality control. One characteristic of our production is flexible processing of orders of many different sizes so that small series and individual production can be produced on short notice in addition to serial production as well.

The installation

If the specifications from the construction phase are observed, all parts can be joined precisely after production. After this final assembly, qualified employees check and document the function and the activation revolutions of the centrifugal clutches at an EDP-supported test base. This continually repeating work step achieves a very high quality standard, and therefore high customer satisfaction.

Our demands to quality and environmental protection

Integration of test sequences, using state of the art measuring and test methods in incoming goods, as well as production-supporting test measures, ensure a consistently high quality standard of the products of Amsbeck Maschinentechnik GmbH. In addition to the quality claim directly targeted at the products, we pursue just as uncompromising directives at our company where commercial processes, customer support during the order, and maintenance of environmental protection are concerned. Thus, all the friction linings used are, of course, free of asbestos and heavy metals. All materials used comply with national and international environmental protection standards and requirements. We preserve raw materials as well as we can in production. Housings are pre-cast in order to have as little material as possible to be removed by machining later.

© copyright 2024 | Amsbeck