Load-free start-up due to centrifugal clutches

Product characteristics of the centrifugal clutches

Do you need a centrifugal clutch for your application? At Amsbeck we are producing centrifugal clutches and centrifugal brakes since 1982. Below you will find an overview of the function and advantages of Amsbeck centrifugal clutches:

Centrifugal clutches operate as a soft start clutch or no-load starting clutch. In this way, the motor can be started without load or operated in no-load operation. This characteristic of centrifugal clutches is used effectively for drives that require a high starting torque.

This makes it possible to choose a engine that is customised to the regular working speed rather than the high start-up torque. The result is a small and cost-efficient engine.

Operating principle of the centrifugal clutch

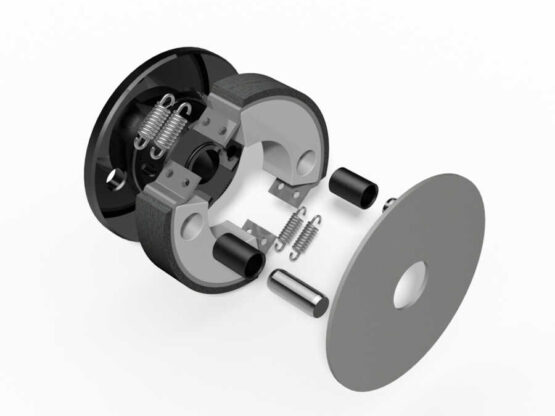

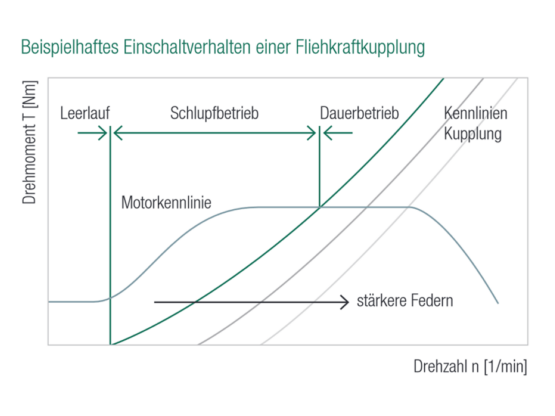

As soon as the weight elements of the centrifugal clutch are set in rotation, they experience a radial force component which accelerates them outward. This force of the centrifugal weights is compensated by the spring forces up to the defined engagement speed.

When the engagement speed is reached, the force of the centrifugal weights exceeds the restraining force of the springs and the friction linings come into contact with the housing of the centrifugal clutch. Torque begints to build up on the housing. The clutch is in slip mode and the application is accelerated rotationally to rated speed. The increase in speed leads to quadratically increasing forces and thus to an increase in torque. Once the nominal speed of the application is reached, the slipping operation ends and the torque is transmitted frictionally.

By varying the springs, the friction material, the size, the number of parallel elements and the operating speed, the engagement speed and torque are determined and adapted to the specific application.

Engaging of centrifugal clutches

Basically, the engagement speed depends on the operating speed of the drive and the power to be transmitted. Since the power of a centrifugal clutch increases quadratically with increasing speed, a minimum operating speed of the drive system is necessary.

The engagement speed of a centrifugal clutch describes the speed at which the mass of the centrifugal weights overcomes the restraining force of the springs due to the centrifugal forces acting on them. By selecting springs of different strengths, which retain the centrifugal weights for different lengths of time, the engagement speed can be varied. By selecting the correct springs, the centrifugal clutch can be optimally adjusted to the requirements of the application.

Using our many years of experience, the engagement speed is set in such a way that a higher torque than necessary is achieved at operating speed. This ensures that the clutch is protected against slipping even in the case of a brief drop in speed.

Heat in centrifugal clutches

Friction generates heat, so a centrifugal clutch converts the friction work completely into heat during the slip phase, so it is extremely important to keep the slip time during which the clutch grinds as short as possible. The organic friction linings used by Amsbeck absorb a very small part of the heat. Almost the entire amount of heat is absorbed by the housing and adjacent parts or dissipated

to the environment by heat conduction.

Construction Types

There are many different types of centrifugal clutches, but at Amsbeck we mainly use two types that have proven themselves in practice over many years

- Centrifugal clutch with free flyweights

- and centrifugal clutch with located pivoting flyweights

In the Amsbeck basic version, the centrifugal elements are mounted on the hub guided via a "dovetail profile", which allows the torque to be transmitted independently of the direction of rotation.

Due to the torque support on the dovetail guide, there is a servo factor which depends on the angle of this guide and increases the value of the torque to be transmitted.

At the centrifugal clutch with located pivoting flyweights the centrifugal elements are guided with low backlash on one side via a pin in a pivot point. The solid carrier plate of the pins increases the damping properties of the coupling and, in conjunction with the bearing of the centrifugal weights, ensures low-vibration and low-noise running. Due to the self-reinforcement, analogous to a duplex drum brake, very high torques are achieved in one direction of rotation. In the opposite direction of rotation, there is no self-reinforcement. As a result, the torque capacity drops to approx. 50 %.

No matter which design is the right one for your application and which engine you use, our couplings are individually tailored to your needs. Whether your engine shaft is keyed or tapered, we will customize the coupling to best fit your engine.

Areas of use for centrifugal clutches

Centrifugal clutches are used in the following areas:

In construction equipment, transport refrigeration equipment, sweepers, mowers, chainsaws, emergency generators, pump drives, lawn mowers, fans, kart racing, stump grinders, descenders, hydro and wind turbines.

Would you like to check whether the principle of the centrifugal clutch is suitable for your application? Please feel free to contact us by phone, contact form or e-mail. Our team will be happy to coordinate the technical design with you.

An overview of our

© copyright 2024 | Amsbeck