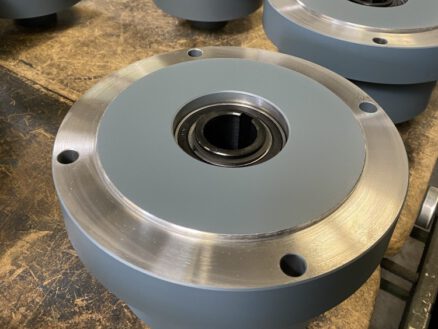

Our current "hottest" centrifugal brake, the 0165-01484

Steelmaking is a demanding process that requires a variety of safety precautions. One of the most important steps in steelmaking is converter technology. One possible safety device against uncontrolled tilting of the converter is the use of a centrifugal brake, as this is purely mechanical and does not use electricity. A converter is a large vessel in which pig iron is converted into steel.

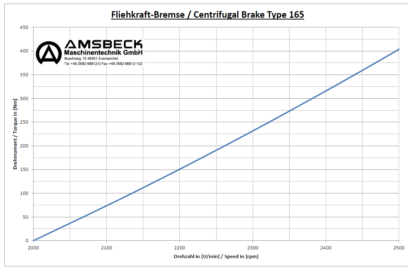

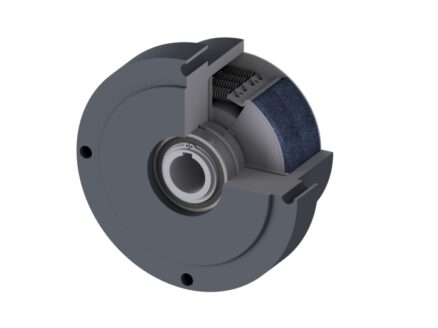

Centrifugal brakes operate on the principle of centrifugal force. They consist of a housing, hub, centrifugal weights, springs and brake linings, which are connected to the converter's axis of rotation via a transmission gear. When the converter tilts to pour, it does so via rotational motion. A centrifugal brake cannot bring the converter to a complete stop, but it can reduce the speed, ensuring the swing-out with a safe and controlled movement. In the event of an unexpected event, such as a malfunction or drive system failure, centrifugal brakes can thus safely slow the converter, minimizing potential hazards. This example is not classic drive technology, but nevertheless demanding and very interesting.

© copyright 2025 | Amsbeck